How to Pour a Concrete Slab for Outdoor Structures in Orange, CA

Concrete Slab Orange

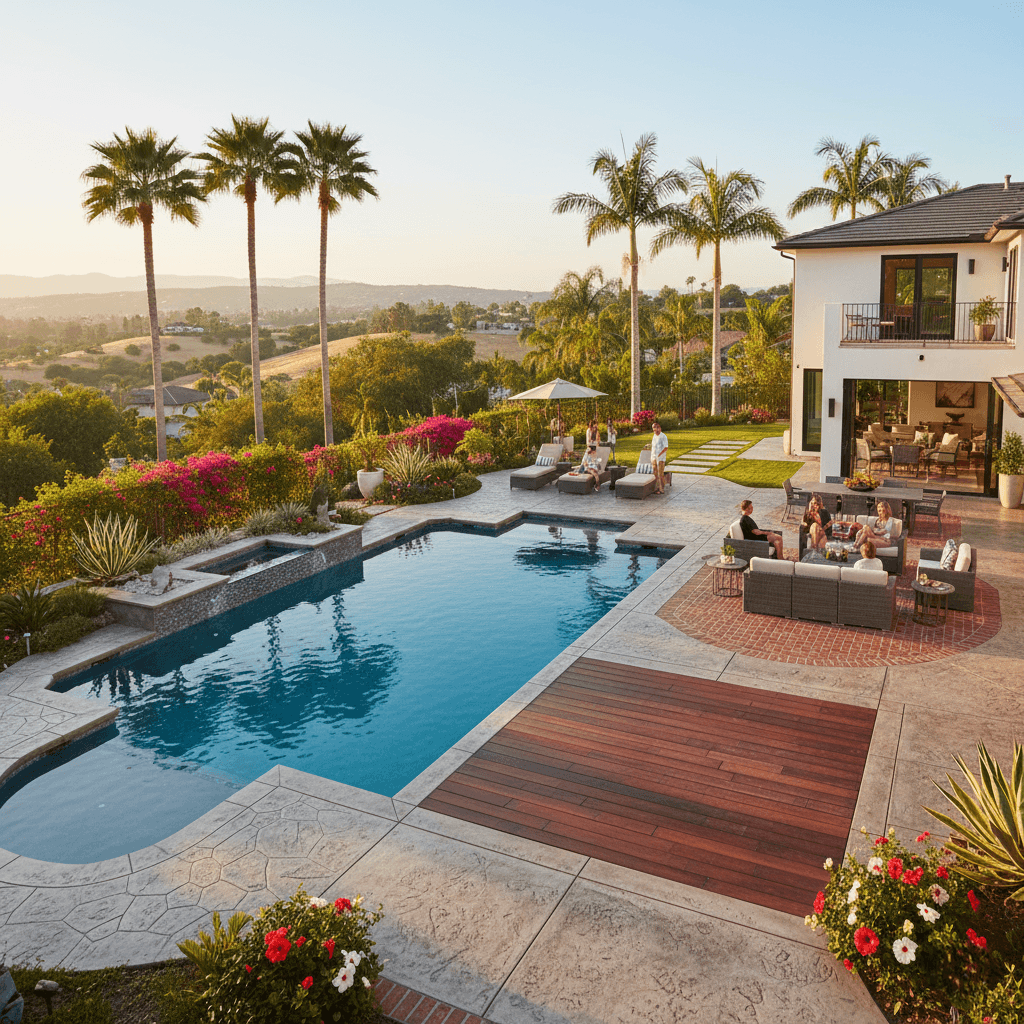

Homeowners in Orange, CA, who are planning to build outdoor features need well-constructed concrete slab foundation systems that will be able to stand up to Orange County’s climate and soils, as well as the overall state of California’s weather and soils. Concrete slabs installed by a professional contractor will help to provide structural integrity to an outdoor feature as well as meet the requirements of all local building codes in Orange County. Knowing the entire process from site prep to final finishes allows a homeowner to have a better understanding of what is involved with the construction project they are working on and makes them more likely to make good, informed decisions regarding their construction project. Using proper procedures in the installation process of a concrete slab can also help to avoid common problems associated with cracked, settled, or damaged due to water, such as moisture damage and damage to the structural integrity of an outdoor structure. A solid plan and a plan that includes quality workmanship when installing a concrete slab will provide a solid base for years to come for many different types of outdoor structures, including but not limited to: a gazebo, shed, outdoor kitchen, and many other various additions to a homeowner’s backyard.

Site Evaluation and Preparation Requirements

Due to the numerous types of soil found in Orange County, it is crucial to evaluate the soil before starting any type of concrete slab project. Specifically, properties located in areas with large amounts of clay may experience soil expansion/contraction due to changing moisture levels. As such, hiring a professional to perform an evaluation will determine the best course of action as far as the appropriate excavation depth and/or base material needed to produce a successful concrete slab project. Many homes are built in Villa Park and Anaheim Hills, where there is a mixture of soil types that make it challenging to establish a single approach for site preparation.

After completing a thorough soil evaluation, the next phase of preparing the site includes accurately staking out the area to define the dimensions of the slab, which are used in conjunction with existing structures to locate the slab properly. Typically, the excavation depth of 6 to 8 inches is standard for most residential outdoor structures; however, when a load-bearing application exists, the excavation depth may need to be greater than 8 inches to accommodate the additional weight. Drainage considerations are also an essential part of the preparation process to help ensure that no water accumulates under the slab, which would compromise its integrity during Orange County’s occasional heavy rainfalls.

Excavation and Base Material Installation

The first step in the excavation process is to remove the grass, topsoil, and debris so that the area hcan becleared to provide a level surface for installing the base material and concrete slab. Orange County Building Codes dictate that the concrete slab must have a minimum thickness of 3.5 inches if it is going to sit directly on the ground, and that the thickness of the concrete slab must increase if the structure is subject to increased loads. In addition, mechanical compaction is used to ensure a stable sub-grade that will resist both settling and movement over time.

A quality base material is also a vital component of the preparation process to help provide structural support and drainage to the concrete slab. For most residential applications, a 4-6 inch compacted gravel base is sufficient; however, there are cases where additional base material may be required to compensate for poor soil conditions. Regardless, each 2-inch lift of gravel must be mechanically compacted prior to placing another layer, thereby ensuring the highest possible density and stability for long-term performance.

Form Construction and Rebar Placement

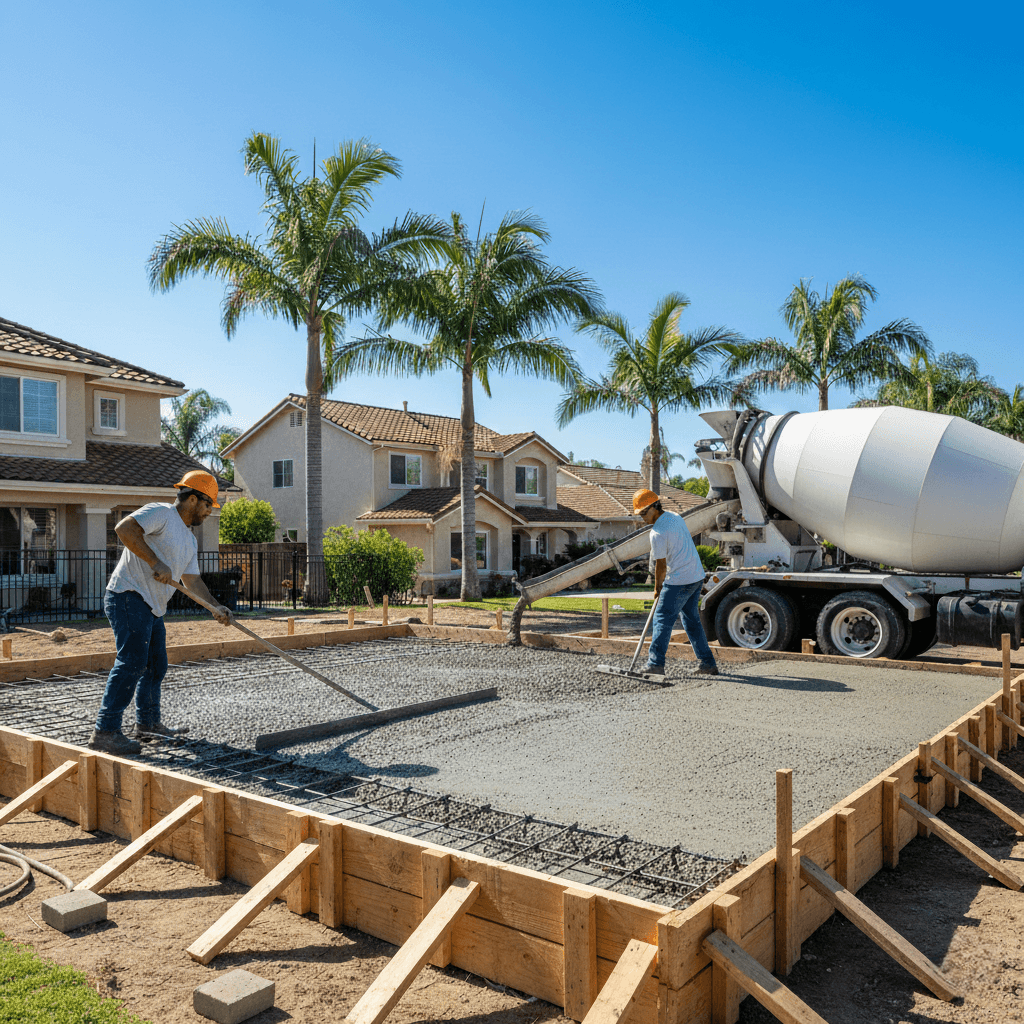

In order to contain the liquid concrete as it sets, precision formwork is necessary to clearly define the boundaries of the concrete slab and to ensure that the slab is the same thickness throughout. The lumber used to construct the forms must be level, square, and properly braced to withstand the pressure exerted by the concrete during the curing process and to prevent the forms from moving or distorting. The stakes that support the forms should be placed every 2-3 feet, and the tops of the stakes should be trimmed flush to the height of the forms to facilitate easy removal and to allow for a smooth finish operation.

Reinforcing steel is also a necessity in the preparation process to improve the durability and resistance to cracking of the concrete slab, particularly in areas prone to seismic activity, such as Orange County. The reinforcing steel consists of half-inch rebar or welded wire mesh, which provides tensile strength to the concrete. To protect against surface cracking and structural failure, the reinforcing steel should be placed in the upper third of the slab thickness.

Concrete Mix Design and Environmental Conditions

Orange County, CA’s unique environmental conditions (temperature, exposure, etc.) dictate that the design of the concrete mix be tailored to meet these needs. All concrete mixes should have a minimum compressive strength of 4,500 psi and should utilize Type V cement to offer protection against sulfate exposure, which is prevalent in certain soil conditions found within Orange County. If the outdoor slab will be subjected to freeze-thaw cycles during the winter months, air entrainment may also be necessary.

To obtain optimal results, the ideal weather conditions for pouring concrete are temperatures above 50°F and clear weather forecasts for a period of at least 24 hours after the concrete has been poured. In addition to the weather conditions, the Santa Ana Winds in Orange County may cause rapid surface drying of the fresh concrete, requiring the use of wind barriers or misting to slow down the moisture loss. The summer heat in Orange County may also require the use of either early morning pours or late afternoon/evening pours to minimize the effects of evaporation on the finishing operations.

Pouring Techniques and Initial Finishing

Pouring concrete is a systematic process that starts at one end of the form and continues until the opposite end of the form is completed. The objective of this process is to pour concrete that is consistently the same thickness throughout the entire slab. Vibration or rodding of the fresh concrete helps to eliminate air pockets and to fully consolidate the concrete around the rrebar Due to their large size, some slabs may require the use of sectional pours to maintain the workability of the concrete and to preserve the quality of the finish.

Following the completion of the pouring of the concrete, the next step in the finishing process is to screed the level of the concrete surface using a straight board that is drawn across the top of the forms to produce a uniform thickness of the concrete and to remove any excess concrete. This process is critical in establishing the correct grade and slope for the concrete slab to direct water away from adjacent structures. It may be necessary to complete multiple passes with the screed to produce the desired level of smoothness and to eliminate any high or low spots in the concrete surface.

Surface Finishing and Texture Application

Once the screeding process has been completed, bull floating is the next step in the finishing process to smooth the surface of the concrete while bringing the “cream” to the top to optimize the finishing operation. It is essential to time the bull floating operation carefully – if the floating occurs too early in the process, it may disturb the settlement of the aggregate particles in the concrete and make the finishing process much more difficult; conversely, delaying the bull floating operation may result in a difficult finishing condition. Additionally, due to the dry nature of Orange County’s climate, the bull floating schedule may need to be expedited in comparison to other regions with higher humidity.

The application of a textured surface to the concrete slab enhances the safety and aesthetics of the finished product, while providing a non-slip surface for outdoor applications. The texture may range from a simple broom finish for utilitarian applications to decorative finishes such as stamping or exposed aggregate. The edging tool is used to create a clean, finished edge at the perimeter of the concrete slab and to help prevent chipping and spalling of the concrete edges.

Curing and Quality Control

Providing adequate moisture and temperature conditions for the concrete to cure is essential to maximize the ultimate strength potential of the concrete over time. Due to the dry climate of Orange County, it is essential to apply a curing compound or to cover the newly placed concrete with plastic sheeting to help retain the moisture in the concrete. A minimum of 7 days of curing time is recommended to ensure the concrete has gained enough strength to withstand the removal of the forms and to accept any applied loads.

Control joints are a mechanism to prevent random cracking of the concrete slab by creating predetermined failure planes in the concrete. The spacing of control joints should not exceed 2-3 times the thickness of the slab in feet, and the control joints should be cut to approximately 25% of the total thickness of the slab. Properly timed and installed control joints will greatly reduce the amount of maintenance that will be required throughout the service life of the concrete slab.

Code Compliance and Professional Installation

Compliance with local building codes, regulations, and ordinances is mandatory for all concrete slab construction projects in Orange County, and the local building codes specify the required minimum thickness, reinforcement, and inspection protocol for concrete slab construction projects. In addition, permits are required for all concrete slab construction projects based on the size of the structure and/or the intended use of the structure. Professional installation of the concrete slab is usually required for all concrete slab construction projects, regardless of the size of the structure. Compliance with local building codes and regulations ensures public safety, protects property value, and ensures compliance with insurance policies.

Orange Concrete Contractor Pros is a leading provider of professional concrete slab construction services that meet all of the local building codes and regulations while providing superior craftsmanship for outdoor structure foundations. We specialize in all aspects of concrete slab construction, from site preparation through finishing, and we strive to deliver durable results that will meet our clients’ outdoor living objectives while providing reliable service in the face of the environmental challenges that exist in Orange County.